Project Portfolio

About Me

CruzCSaucedo@gmail.com

I am a Mechanical Engineer with a strong focus in aerospace systems, propulsion, and advanced engineering analysis. I earned my Bachelor of Science in Mechanical Engineering with an Aerospace Option from Oregon State University, graduating Cum Laude, and I am currently completing my Master of Engineering in Mechanical Engineering, where I maintain a 4.0 GPA.

My academic background includes extensive coursework in rocket propulsion, space systems engineering, finite element analysis, systems dynamics and control, thermodynamics, heat transfer, and composites manufacturing. Through both my undergraduate and graduate studies, I have developed a strong foundation in applying engineering theory to real-world aerospace and mechanical systems.

During my internship at Altitude Aerospace in Tigard, Oregon, I gained hands-on experience supporting aircraft engineering and certification documentation. Working alongside experienced engineers strengthened my ability to translate classroom knowledge into practical solutions while maintaining a strong focus on quality, safety, and precision.

What drives me most is solving complex technical problems and continuously improving my skills as an engineer. I take pride in being detail-oriented, dependable, and highly motivated to contribute to high-performance aerospace systems. Whether working independently or as part of a multidisciplinary team, I strive to bring professionalism, curiosity, and integrity to every project.

This portfolio showcases selected academic, technical, and professional projects that reflect my growth as an engineer and my commitment to excellence in the aerospace field. I am excited to continue developing my career in aerospace engineering and contributing to innovative, reliable, and impactful engineering solutions.

Cruz Saucedo

Masters of Engineering, Mechanical Engineering

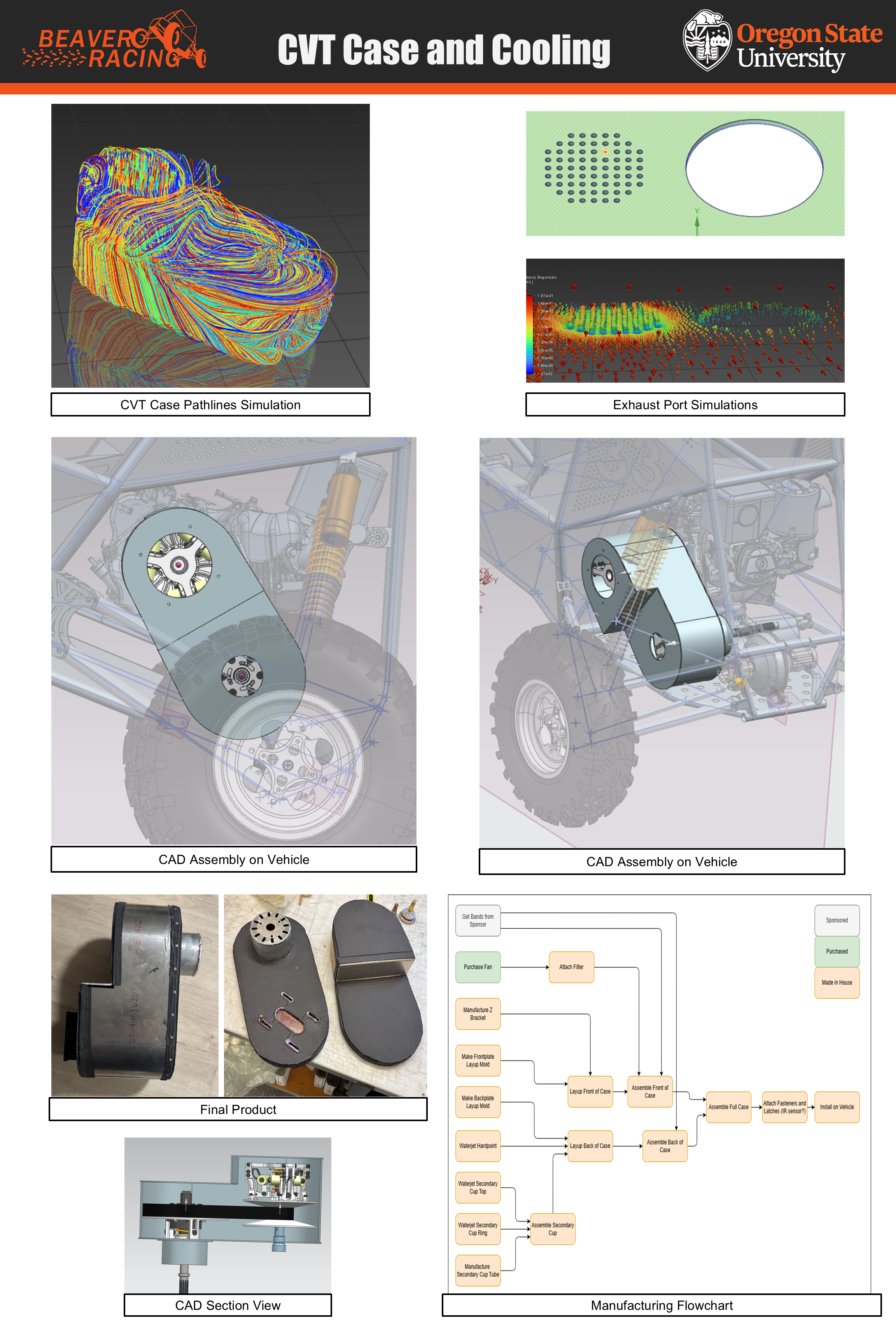

Beaver Racing

The Baja SAE vehicle uses a continuously variable transmission (CVT) to deliver smooth and efficient power across a wide range of off-road conditions. While this system offers excellent performance benefits, the constant adjustment of the CVT generates significant heat from friction within the belt and pulleys. If left unmanaged, excessive heat can lead to belt slippage, reduced efficiency, and potential mechanical failure, making effective cooling critical to overall vehicle reliability.

This project focused on designing a structurally sound and accessible CVT case paired with an improved cooling strategy for the Oregon State University Baja SAE car. The goal was to optimize airflow and thermal management while maintaining ease of maintenance and minimizing added weight. Due to limited existing data on CVT thermal behavior, this work also emphasized gathering insight into how current cooling solutions perform. The resulting design aims to keep the CVT operating within optimal temperature ranges, improving durability, power delivery, and overall drivetrain performance.

Rocket Propulsion

This project required the end-to-end design and evaluation of a booster propulsion system capable of delivering a 100,000 kg payload while meeting strict performance, geometric, and operational constraints. The task demanded translating mission requirements—ΔV, thrust-to-weight ratio, burn time, mass fraction, and vehicle diameter—into feasible propulsion architectures and hardware designs. Multiple propulsion concepts were developed from first principles, including liquid, solid, and hybrid rocket engines, each constrained to realistic chamber pressures, nozzle geometries, and structural limits.

For each propulsion concept, the work involved sizing nozzles, combustion chambers, propellant tanks, and structural mass while balancing performance, reliability, and environmental impact. Thermochemical performance was evaluated using NASA CEA, while vehicle trajectory and ΔV were modeled numerically using Python-based integration methods. Design parameters such as burn time, area ratio, and propellant selection were iterated to meet thrust and mission requirements, forcing tradeoffs between efficiency, complexity, manufacturability, and risk.

The project ultimately functioned as a real-world engineering trade study, requiring systems-level thinking rather than isolated calculations. Final recommendations were justified by quantitative analysis, engineering feasibility, and operational considerations, mirroring the decision-making process used in early-phase launch vehicle design and propulsion concept selection.

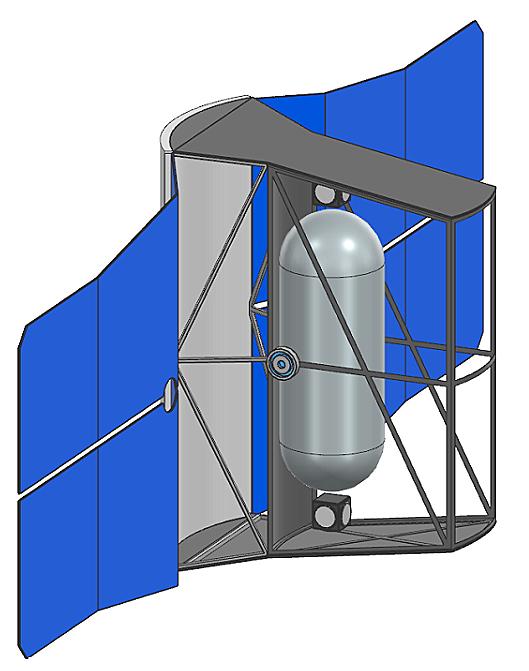

Top Level Space Mission Design

Project SUNRISE was a full-scale spacecraft mission design project that demanded end-to-end systems engineering under extreme physical, operational, and programmatic constraints. The task was to design a NASA-class solar observatory capable of delivering an 8,100 kg spacecraft into a highly elliptical heliocentric orbit with a 5.3 million km perihelion, significantly closer to the Sun than any prior mission. This required translating ambitious science goals into concrete engineering requirements while managing tightly coupled tradeoffs between propulsion, power, thermal control, structures, communications, and launch vehicle capability.

The project required rigorous requirements-driven decision making rather than isolated subsystem design. Key challenges included closing a 45+ km/s total ΔV budget, selecting a launch vehicle that balanced performance and feasibility, and designing a spacecraft propulsion system capable of sustaining decades-long low-thrust operations without gravity assists. The team evaluated multiple mission architectures before pivoting away from Venus flybys and committing to a fully electric-propulsion-driven trajectory, forcing deep analysis of Hall thruster performance, solar array sizing, radiator mass, thermal rejection limits, and mission timeline risk. Every subsystem decision directly impacted others, requiring constant iteration at the system level.

As Systems Engineering Lead, this project demanded coordination across disciplines to ensure the spacecraft could survive extreme solar radiation, thermal flux, structural launch loads, and long-duration operations while remaining serviceable and controllable. The final design integrated heritage solutions from Parker Solar Probe with new scaling challenges, resulting in a spacecraft over 12× more massive than PSP but capable of autonomous orbit control, robust thermal protection, redundant propulsion, and continuous power management near the Sun. SUNRISE functioned as a realistic early-phase NASA mission study, mirroring the complexity, ambiguity, and trade-space exploration faced in real aerospace system design.

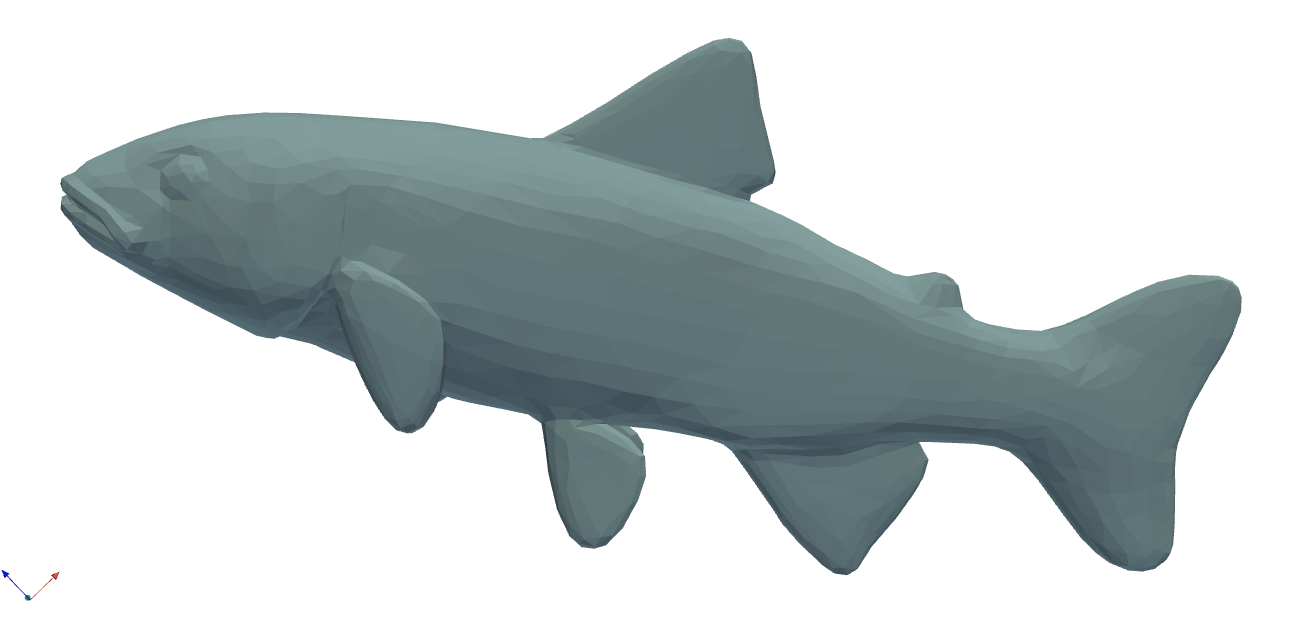

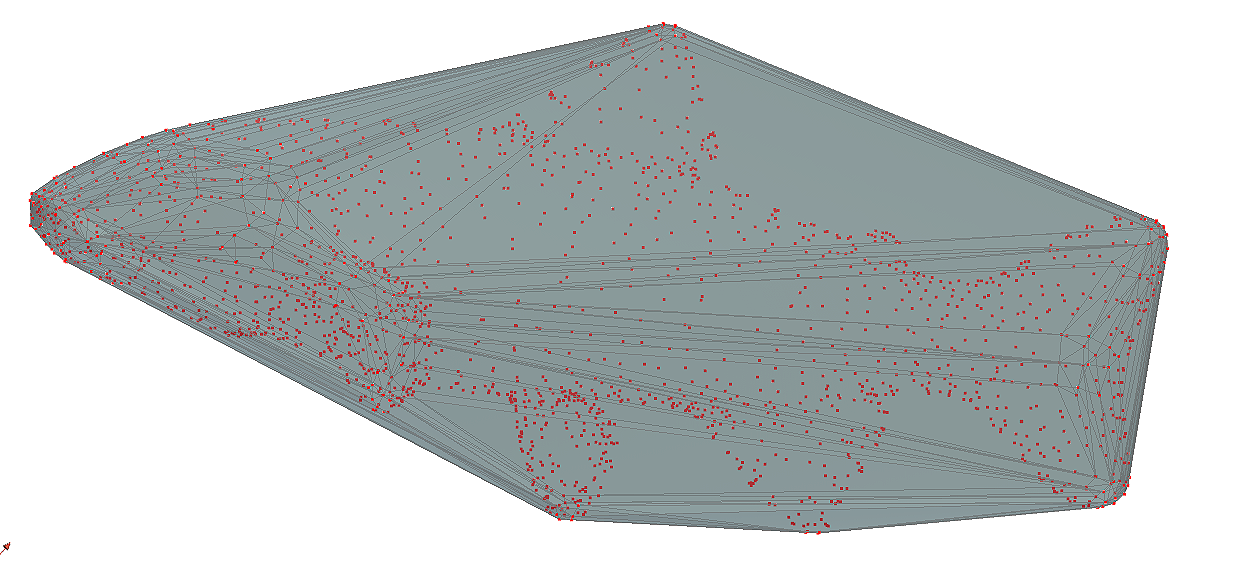

Convex Hull Algorithm

This project required the design and implementation of a robust 3D convex hull algorithm capable of identifying the outer boundary of complex point clouds. The task went beyond applying a known formula and instead demanded algorithm selection, geometric reasoning, and careful handling of numerical and topological edge cases common in real-world spatial data. Two established approaches—gift wrapping and tetrahedral (Quickhull-style) expansion—were investigated and implemented to evaluate their feasibility, correctness, and computational behavior in three dimensions.

The core challenge was ensuring that newly generated faces preserved global convexity while avoiding redundant or invalid geometry. This required managing face orientation, detecting horizon edges, classifying points relative to planes, and defining clear termination conditions. The tetrahedral expansion method was successfully implemented, starting from non-coplanar extreme points and iteratively expanding the hull by identifying visible faces and propagating along horizon edges. The algorithm was validated on both structured meshes and randomized point clouds, demonstrating correct enclosure of complex geometries.

Beyond implementation, the project emphasized engineering judgment and algorithmic tradeoffs. Limitations such as degenerate extreme-point configurations, numerical precision issues, and efficiency concerns were identified and analyzed, with proposed solutions grounded in computational geometry literature. The result is a working 3D convex hull solver paired with a clear understanding of where and why such algorithms fail—an experience directly applicable to geometry processing, simulation preprocessing, collision detection, and design automation workflows.

bEaV Bike

As part of a multidisciplinary team, we designed and developed the bEaV Bike 2023, an electric commuter bicycle emphasizing sleek design, modern technology, and environmental sustainability. Our design process began with brainstorming sketches, iterative refinement, and a SWOT analysis to identify strengths such as aerodynamics, electric assistance, and modern aesthetics, while addressing challenges like weight, battery limitations, and security.

We produced detailed engineering drawings and 3D isometric models for all major components, including the frame, wheels, pedals, handlebars, and accessories such as a bike light and phone holder. These models informed the assembly design, bill of materials, and exploded views, ensuring manufacturability and integration of custom parts unique to our brand. The final presentation included photorealistic renderings showcasing material choices—brushed aluminum frame, ABS pedals, carbon steel wheels, and sandblasted accessories—under realistic studio lighting conditions.

The project highlighted skills in CAD modeling, product design, materials selection, and collaborative engineering, producing a commuter bike tailored to high-income, environmentally conscious urban riders. This experience demonstrated our ability to combine technical engineering proficiency with design thinking and market considerations to create a functional, aesthetic, and manufacturable product.